Autonomous technology is advancing faster than ever, and at the heart of its evolution lies a powerful capability: 3D obstacle avoidance. Whether in drones, self-driving vehicles, or warehouse robots, the ability to detect, understand, and avoid obstacles in three dimensions is critical for safety and efficiency. Without it, automation wouldn’t be trusted in dynamic, real-world environments filled with unpredictable challenges.

Businesses today need smarter machines that can operate in busy warehouses, cluttered construction sites, or outdoor fields — and navigate with the precision of a human. That’s exactly what modern systems like those offered by MRDVS are designed to do: enable real-time, high-accuracy obstacle avoidance using advanced 3D perception.

In this article, we’ll explore how 3D obstacle avoidance works, what makes it superior to older 2D methods, and how it’s already revolutionizing industries like logistics, agriculture, robotics, and more.

What Is 3D Obstacle Avoidance?

3D obstacle avoidance is a robotic system’s ability to detect and navigate around obstacles using three-dimensional environmental data. This system not only recognizes an object’s presence but also understands its depth, size, shape, and position in space. By collecting real-time 3D data, the machine can plan routes, stop or re-route if necessary, and adapt to its environment without human input.

Unlike 2D methods that only operate on a flat plane, 3D systems interpret vertical and horizontal elements, offering depth perception similar to human vision. This capability is especially critical in areas with uneven surfaces, varying heights, or moving obstacles.

How 3D Obstacle Avoidance Works

To perform intelligent navigation, a 3D obstacle avoidance system uses a combination of sensors and software. Here’s a simplified breakdown:

- Sensing: The robot captures spatial data using LiDAR, stereo cameras, depth cameras, or ToF sensors.

- Mapping: This data is used to construct a 3D map of the environment using algorithms like SLAM (Simultaneous Localization and Mapping).

- Object Detection: Obstacles are identified, classified (static or dynamic), and located.

- Path Planning: The robot uses AI algorithms to calculate a safe, optimized route.

- Real-Time Adaptation: The system constantly updates as the robot moves, recalculating paths when new obstacles appear.

Key Technologies Used in 3D Obstacle Avoidance

| Technology | Function | Common Use Case |

| LiDAR | Laser-based scanning to detect object shape and depth | Autonomous vehicles, drones |

| Stereo Cameras | Capture images from two angles to calculate depth | Indoor robots, warehouse navigation |

| Time-of-Flight | Measures light travel time for depth sensing | Mobile robots, smart drones |

| RGB-D Cameras | Provide color and depth for scene understanding | Human interaction, collaborative robots |

These systems work together to build a real-time spatial model of the environment, enabling safe, dynamic movement.

Benefits of 3D Obstacle Avoidance in Automation

- Safer Navigation

With real-time perception of obstacles, robots avoid collisions, protecting people, products, and infrastructure. - Increased Efficiency

Smarter path planning means shorter travel distances and fewer interruptions, boosting operational throughput. - Adaptability to Dynamic Environments

3D obstacle avoidance allows machines to work effectively in constantly changing or crowded settings without human intervention. - Cost Savings

By reducing the risk of damage, system errors, and downtime, 3D navigation minimizes long-term maintenance and repair costs. - Compatibility Across Industries

From drones in agriculture to AGVs in factories, this technology scales across use cases without significant customization.

Real-World Applications of 3D Obstacle Avoidance

Autonomous Vehicles

In self-driving cars, 3D obstacle avoidance is essential for detecting pedestrians, cyclists, traffic barriers, and other vehicles in real time. It ensures safe driving decisions by interpreting complex road environments.

Drones and UAVs

Aerial robots equipped with 3D perception can fly through forests, avoid power lines, and navigate indoors—all without hitting obstacles. This makes them ideal for inspections, deliveries, and surveying.

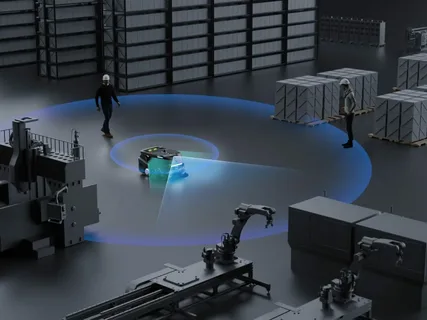

Warehousing and Logistics

Autonomous mobile robots (AMRs) in smart warehouses use 3D obstacle detection to move around shelves, avoid workers, and deliver goods without disruption, even in tight or busy spaces.

Agriculture

Robots in agriculture use 3D sensors to steer clear of animals, trees, irrigation systems, and rough terrain. They enable precise tasks like weeding, seeding, and harvesting.

Construction and Mining

Heavy-duty autonomous machines equipped with 3D sensors detect uneven ground, cliffs, debris, or moving machinery, allowing for safer and more efficient operations.

2D vs 3D Obstacle Avoidance: A Clear Difference

| Feature | 2D Obstacle Avoidance | 3D Obstacle Avoidance |

| Depth Perception | None | Yes |

| Obstacle Classification | Limited | Accurate and detailed |

| Handling of Vertical Objects | Poor | Excellent |

| Dynamic Path Adjustment | Basic | Real-Time and Adaptive |

| Environmental Complexity | Low to Moderate | High |

While 2D systems may suffice in basic indoor applications, 3D obstacle avoidance is essential in dynamic, unpredictable, or complex environments.

Eye-in-Hand vs Eye-to-Hand Sensor Placement

Eye-in-Hand: The sensor (usually a camera) is mounted on the robot’s end effector. This gives the robot the ability to move the sensor dynamically and scan from different angles.

Eye-to-Hand: The sensor is placed in a fixed position, such as above a workspace. This setup offers a wide, stable view of the environment and is useful for monitoring large areas or conveyor belts.

Choosing the right configuration depends on your application’s mobility, precision, and speed requirements.

Challenges and Solutions

Despite its advantages, 3D obstacle avoidance comes with some challenges:

- Sensor Cost: High-end 3D sensors like LiDAR can be expensive, though costs are dropping over time.

- Environmental Conditions: Dust, water, or lighting changes can affect camera accuracy.

- Processing Power: Real-time 3D mapping and object detection demand fast processors or edge computing.

To overcome these challenges, modern systems incorporate sensor fusion (combining data from multiple sensors) and AI algorithms to improve accuracy, even in noisy environments.

Future of 3D Obstacle Avoidance

As robotics continues to evolve, we can expect the following advancements in obstacle avoidance:

- AI-Driven Path Optimization: Smarter algorithms that learn over time and improve decision-making.

- Miniaturization: Smaller, more affordable sensors for use in compact or wearable robots.

- Collaborative Robotics: 3D obstacle avoidance will be critical for robots that work alongside humans safely.

- 5G Connectivity: Enables faster data sharing between robots and cloud-based control systems.

These innovations will open new opportunities for industries looking to implement autonomous systems safely and efficiently.

Conclusion

3D obstacle avoidance is the backbone of safe and intelligent robotic movement. It allows machines to perceive their environment in full depth, assess risks in real time, and make smart navigation decisions—without manual input. Whether you’re deploying autonomous vehicles, delivery drones, or mobile warehouse robots, this technology ensures that your systems operate safely, adaptively, and efficiently in any environment.

If you’re considering advanced 3D navigation for your business, integrating a high-performance obstacle avoidance system is no longer optional—it’s essential. The right solution will reduce downtime, increase safety, and future-proof your automation strategy.